How to make a self-leveling floor with their hands

Do It Yourself Educational Program / / December 19, 2019

1. Prepare materials

You will need:

- leveling the mixture;

- water;

- Primers, deep penetration;

- tile adhesive or assembly foam;

- container for mixing;

- Needle roller with a long handle;

- wide spatula;

- drill with a whisk;

- roller or brush;

- bubble level;

- roulette;

- pencil;

- staple gun;

- broom or vacuum cleaner;

- knife;

- mokrostupy;

- Damper tape.

2. Calculate the exact amount of the mixture

Since shading is made in one go, it is important to initially calculate the required amount of solution. To find out how many bags leveling mixture is required, perform some simple measurements and calculations.

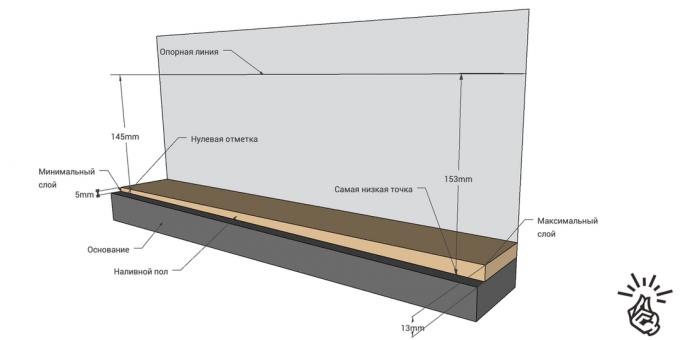

Note, by laser or ordinary skill arbitrary horizontal line on the walls on the perimeter of the room. Measure the distance from this point to the floor in several places in each wall and define a zero, that is the highest point of the base. In the same way, find the lowest point.

The results of this example turned 152, 149, 145 or 153 mm. The lowest number is the highest point, or zero, the largest - the lowest. The height difference makes the difference therebetween, i.e. 8 mm (153 - 145 = 8).

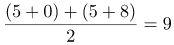

Check on the packaging minimum permissible thickness of the floor. Usually it is 3-5 mm. Take, for example 5 mm. We can now calculate the average layer thickness, which need for counting the number of mixture. We use a simple formula:

Where:

- a - the minimum permissible thickness of the floor;

- b - the height zero (0);

- c - vertical drop;

- d - the average thickness of the floor.

In this case, the middle layer 9 mm is obtained:

To calculate the necessary amount of dry mix, look at the packaging of its consumption. This usually 1.6-1.8 kg / m at a layer thickness of 1 mm. If the middle layer is 9 mm, then the obtained 1,6 × 9 = 14.4 kg / m². That is, for example, for the room 12 m² need 14,4 × 12 = 172.8 kg. Or seven bags of 25 kg.

3. Prepare the base

The thoroughness of the preparation of the base will depend on the quality of the cast floor. Surface should be completely dry and solid.

Remove all loose material, seal the cracks, scrape off the stains of paint and plaster. Remove all debris, thoroughly sweep or vacuum the surface.

Fill the gap between the wall and the floor by means of tile adhesive or foam, the mixture did not get into them and not podtopilo neighbors below. In order to prevent spreading into neighboring rooms set in the doorway strips of drywall or wooden blocks.

4. Apply the primer

Before pouring necessarily need to cover the base primer deep penetration. If you do not do this, it will decrease the adhesion of the mixture and the moisture is absorbed rapidly from the solution that will lead to a deterioration in spreadability.

Spread the soil according to the instructions on the packaging and cover the base with two or three layers with a roller or wide brush. Each subsequent layer is applied after drying of the previous.

5. Install the damping tape

To compensate for the linear extensions of self-leveling floor glue or staple gun attach the edge band on the walls around the perimeter of the room.

If the screed thickness less than 10 mm, the damper tape can be omitted. When the layer more than 1 cm, or using underfloor heating application tape is required.

6. Make markup

Leveling mixtures have good flow, but do not align themselves contrary to popular misconception. They must be evenly distributed over the surface, and for this we need markup.

Using the reference line printed on the wall in the second step, to make a mark, which will serve as the upper boundary of self-leveling floor. For this mark the zero point and add it to the minimum thickness of the layer, which is recommended by the manufacturer of the mixture.

In this example, the zero point is at around 145 mm from the reference line, and the minimum layer is 5 mm. So 145 mm is necessary to take 5 mm layer thickness. In the end, it turns out that for a perfectly flat surface, we need to pour a mixture of the marks on 140 mm below the reference line.

Make a pencil or marker dashes around the room at the desired height, and then combine them into a single line using a level, rules, wooden slats, or any other similar object.

7. Prepare a mixture

Pour into a container of cold pure water according to proportions indicated on the package, and to pour the contents of the bag. Stir with a mixer until smooth. Use low speed to avoid air entrainment and bubble formation.

Let the mixture stand for 3-5 minutes to complete a chemical process, and again mix. In any case not exceed the maximum amount of water. Otherwise, there will bundle the solution to deteriorate the strength of self-leveling floor and it can crack.

Prepared mixture should be used for 30-40 minutes, so you have to work very quickly and it is desirable to assistantWhich is parallel to the kneading portion of the following while you pour the first.

8. Fill surface

Since the distal end of the room, carefully pour the solution stripes and uniformly distribute it to the ground. If necessary, help yourself wide spatula.

Several times rolled drenched the surface with a spiked roller to expel air bubbles and distribute the composition over the floor. For effective operation of the needle height should be twice the thickness of the screed layer. Otherwise, the composition will be "wound" on the platen, resulting in the formation of waves.

Navigate through the tie layer is necessary in special studded grounds for shoes - mokrostupah. But if the area of the inlet gender small, with a neat work you can do without them.

9. wait until dry

Depending on the thickness of the floor of the inlet drying time may be different. As a rule, after 4-6 hours it is already possible to walk. It is important to avoid drafts and direct sunlight to all the evenly and gradually dry.

Stack topcoat over the floor only after the complete drying of the screed. Usually no earlier than next week. Otherwise there is a risk of its deformation by the evaporation of residual moisture.

10. Trim damper tape

The final touch - trimming damper tape on the perimeter walls. Take a sharp knife and carefully remove protruding above the surface of the floor tape.

Details of the whole process is, video.

see also⚒👷♂️🏠

- How to adjust the plastic windows and save on wizard

- How to lay laminate

- How to lay linoleum

- How to install interior doors

- How to install the switch